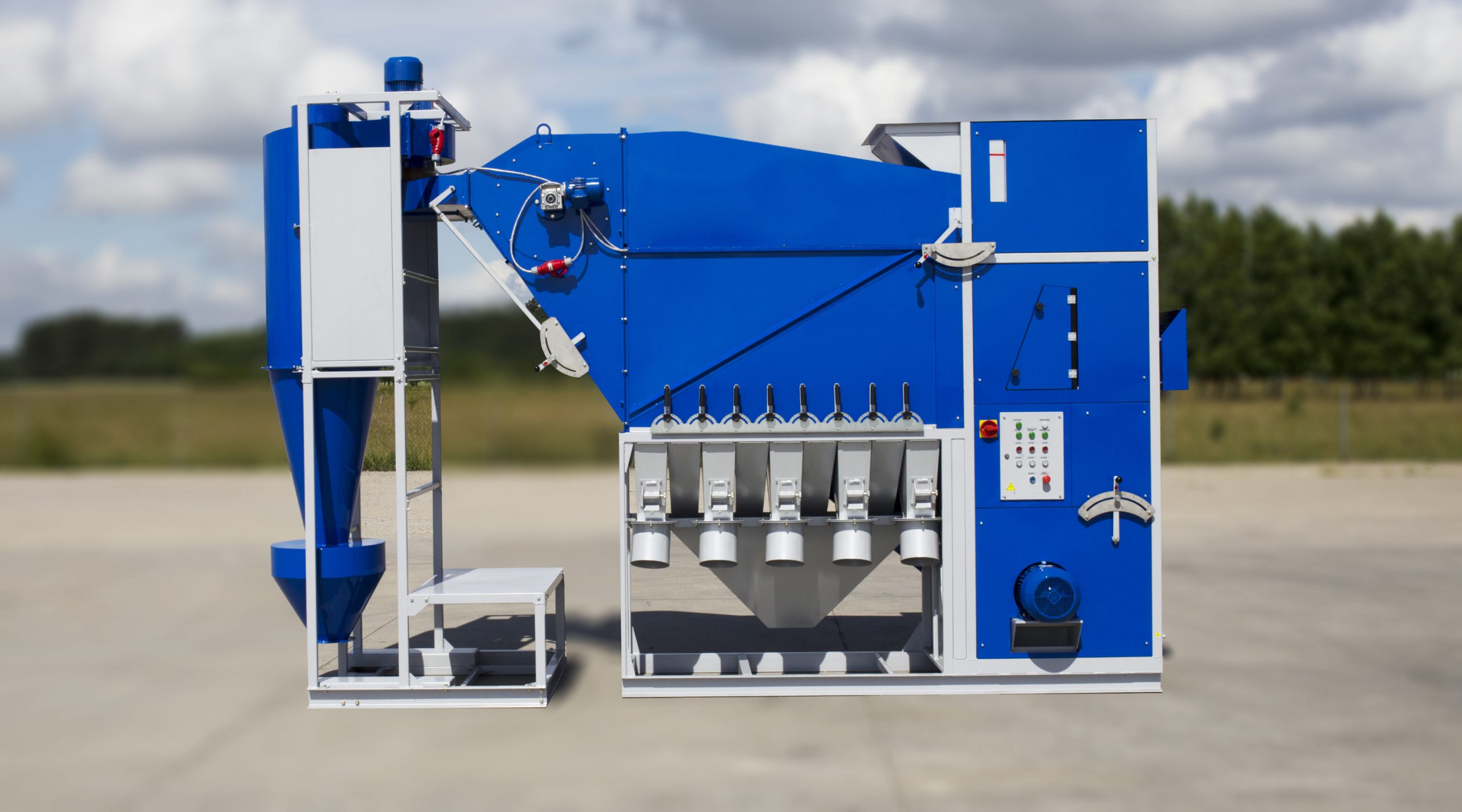

ASM TECHNOLOGY SP. Z O. O. - MANUFACTURER OF MACHINERY

FOR AGRICULTURE AND THE FOOD INDUSTRY

ASM TECHNOLOGY is a brand on the European map of the agricultural and food industry machinery manufacturers.

Basing on long-term development of our grain sorting technology and experience dating back to 2001, we offer you modern, high-efficiency machines for cleaning and sorting of grain. Specialized, precise production providing you with access to modern and effective solutions in the field of cleaning and processing seeds of grains, leguminous and oil plants.

REPORTS FROM THE FAIR

Opolagra exhibition (Kamień Śląski)

Agricultural and Food Trade Fair in České Budějovice

AGRO SHOW in Bednary

Messe AGRI TECHNICA 2022

ASM SEPARATORS’ UNIQUENESS

ASM separators are used to select healthy, high-quality seeds. They can work with any material

(grains, grasses, leguminous and oil plants), regardless of its moisture content.

ASM separators work with loose material of any type and humidity

in four modes:

– drying,

– preliminary cleaning,

– proper cleaning,

– calibration (separation) according to the specific weight.

ASM high-efficiency separators (up to 100 t / h) and low energy consumption (up to 20 kW / h)

enable drying of the raw material with air, with a yield from 1.5% to 20% per cycle. At the same time,

they remove biological contaminants (fungi, bugs, beetles) and reduce the costs of further seed storage.

TECHNOLOGY

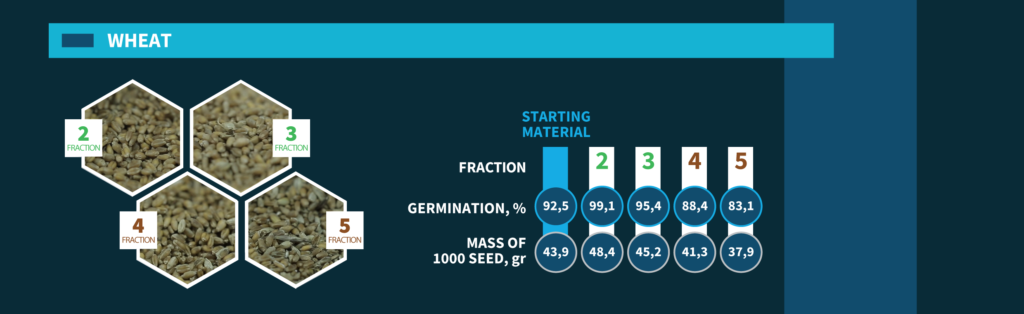

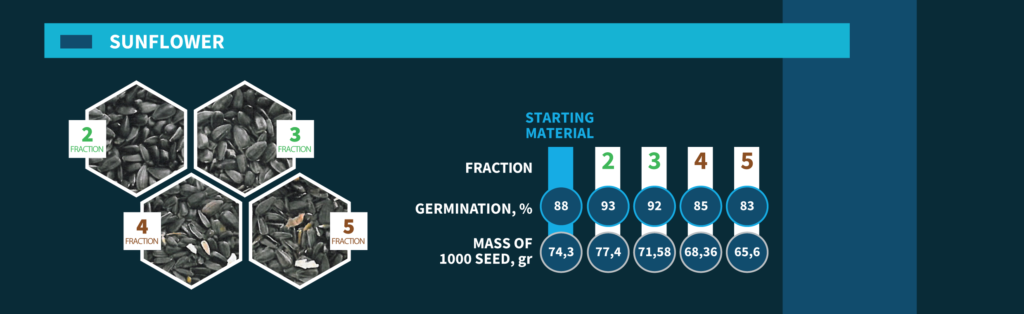

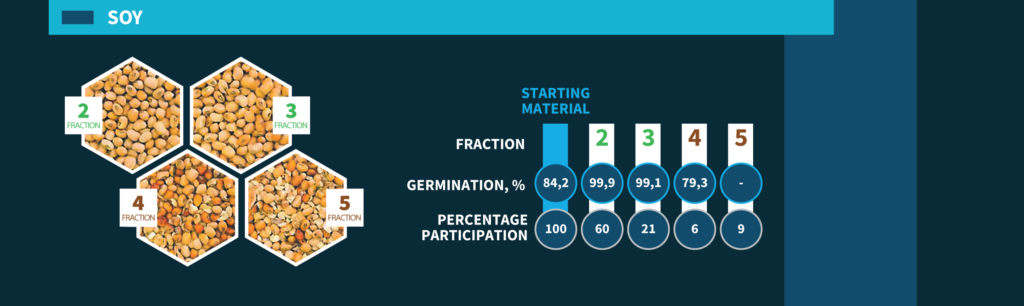

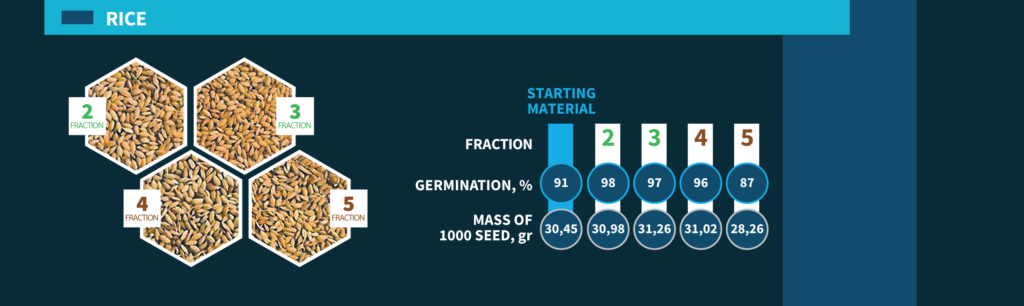

ASM separators sort seeds basing on specific weight. Our technology can be successfully used in:

– agriculture – when cleaning seed, it allows for selecting the most biologically valuable seeds, which translates into an increase in yields of up to 40%!

– storage – pre-cleaning mode allows to prepare grain for storage, and the drying function allows for reduction of seed moisture to ensure proper storage conditions.

– processing industry – numerous separator operation modes allow for effective cleaning of various types of raw material for the needs of mills, granaries (kaszarni), feed rooms (paszarni), oil mills, distilleries, breweries, food industry plants and others.

Cleans all kinds of seeds:

grains, grasses, leguminous and oil plants, etc.

Seed separation

based on specific weight

The moisture content of the raw material does not matter

Innovative, patented technology

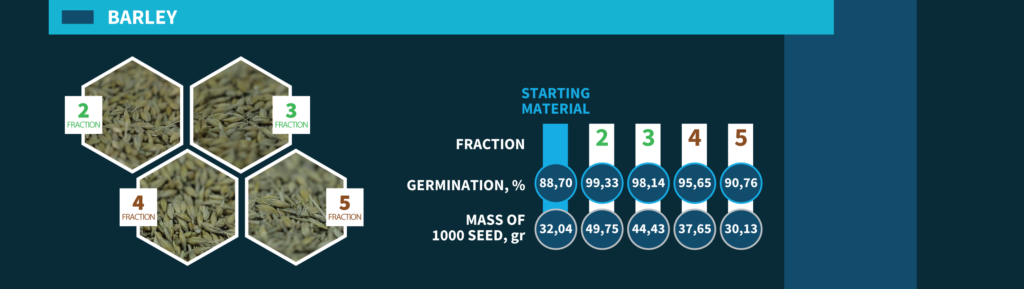

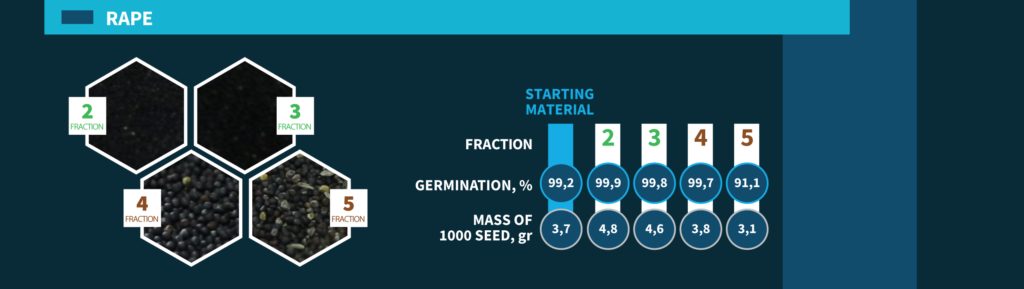

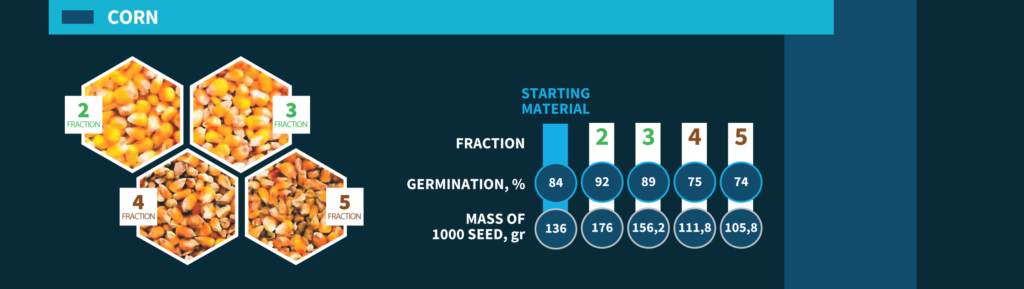

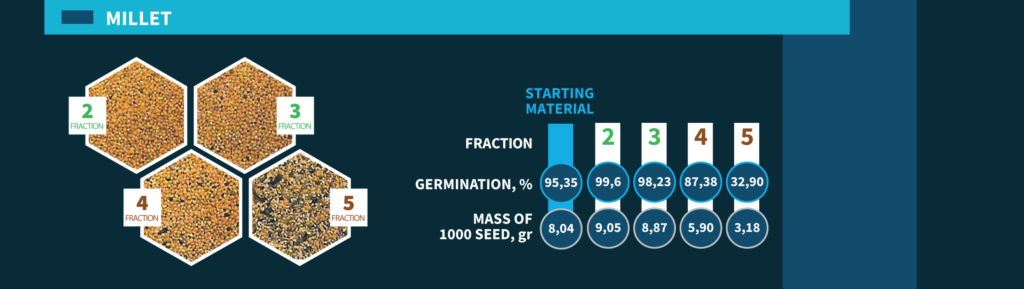

The effectiveness of cleaning

is confirmed by research carried out by the Bialystok University of Technology

High performance

Segregation of seeds into 6 fractions

Low energy consumption

low operating costs.

Quick retooling

in the event of a raw material change (no sieves)

4 operating modes:

drying, pre-cleaning, proper cleaning, calibration (separation).

Effective use

in farms, grain collection points, processing plants

Extremely easy to use